As a crucial product identifier, hang tags carry essential product information and embody the brand image. A well-designed hang tag can enhance the overall quality of a product and strengthen consumer brand recognition. However, hang tag design isn’t a haphazard process; it must adhere to certain standards and precautions to ensure accurate information and effective delivery. Below, REENYOUNG will discuss hang tag design in detail, focusing on design considerations and printing-related elements.

Information Accuracy:

The hang tag must clearly and accurately present important information such as the product name, brand logo, size, ingredients, and washing instructions. This information is crucial for consumers to understand the product’s properties and usage, and must be accurate to avoid misleading consumers.

Regulatory Compliance:

The hang tag design must comply with relevant national regulations and standards, such as GB5296.4-1998 “Instructions for Use of Consumer Goods – Textiles and Clothing.” These regulations specify the required information content and format on the hang tag.

Design Consistency:

The hang tag’s design should align with the brand’s overall image and positioning. Jicai believes that hang tag design can strengthen the brand’s impression in consumers’ minds and enhance brand recognition.

Material and Environmental Protection:

The hang tag’s material should be sturdy and durable to ensure it remains intact throughout the product’s lifecycle. Furthermore, the material selection should be environmentally friendly, choosing recyclable and sustainable materials to meet the environmental demands of modern consumers.

Considerations for Hang Tag Design

Details:

The design, text, and edge treatment on a hang tag should reflect meticulous attention to detail. The design should be clear and elegant, the text layout should be neat and standardized, and the edges should be smooth and free of burrs. These details enhance the overall quality of the hang tag.

Readability:

The text, numbers, and symbols on the hang tag should be legible, avoiding blurriness or illegibility. The font size and color contrast should be appropriate to ensure consumers can easily read and understand the information on the hang tag.

Personalized Design:

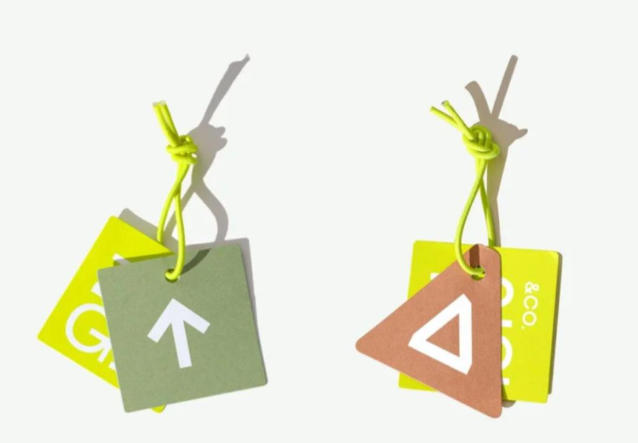

Hang tags can be personalized based on brand characteristics and market demand. Personalization can include customization of shape, color, font, and pattern to match the brand’s image and style. However, personalization should not affect the readability or accuracy of the information on the hang tag.

Cost and Benefit:

Jicai believes in a comprehensive consideration of cost and benefit when designing hang tags. Choosing the appropriate material, size, and printing process can ensure that the hang tag not only meets the brand image and market demand, but also achieves good cost control.

Adaptability:

Hang tag design should adapt to the needs of different markets and consumers. For example, for international markets, it may be necessary to consider the needs of consumers with different languages and cultural backgrounds. Furthermore, hangtag designs should also adapt to the needs of different sales channels and display methods.

Hangtag Printing Factors

Standard Sizes:

5*9cm or 4.5*9cm: Suitable for a variety of products, commonly found on clothing, luggage, shoes, and other items;

2*5cm or 3*7cm: Suitable for gifts, small items, and other specialty items;

7*12cm or 8*14cm: Suitable for high-end clothing, items with larger packaging, and other specialty items.

Standard hangtag sizes vary depending on product type and brand requirements. These sizes offer price advantages for mass customization and are easily adaptable to the needs of different products. However, companies can also design hangtags in other sizes, such as circular, triangular, oval, and other irregular shapes, based on their own requirements or product characteristics.

Printing Process:

Hangtag printing processes include hot stamping, hot foil stamping, UV printing, and embossing. These techniques can significantly enhance the quality and visual appeal of the hangtag. For example, hot stamping with gold and silver foil, commonly used in high-end color printing, can create a unique metallic effect, enhancing the luxurious feel of the hangtag. UV printing adds a layer of varnish to the hangtag surface, effectively protecting the surface and enhancing the texture. Embossing can create raised or recessed patterns and text on the hangtag surface, enhancing the three-dimensional effect.

Die-cutting and Forming:

Die-cutting is the process of preparing the designed hangtag graphic with a die cutter for cutting. Die-cutting allows the hangtag to have a variety of shapes and edge finishes. It also ensures that the size and shape of the hangtag meet the design requirements.

Color Matching:

Color is an important component of hangtag design. Choosing a color combination that suits the brand can enhance the visual impact of the hangtag. The colors should coordinate with the brand’s primary color scheme, while also considering color contrast and readability. Bright colors can attract attention, but extreme colors should be careful not to be too glaring. Subtle colors can convey a sense of elegance and tranquility.

Hangtag design must adhere to standards for information accuracy, regulatory compliance, design consistency, material and environmental friendliness, and pay attention to details, readability, personalized design, cost-effectiveness, and adaptability. Furthermore, when it comes to printing, Jicai reminds designers to consider factors such as size, printing process, die-cutting and molding, and color matching. Through careful planning and execution, a hangtag can be designed that not only meets regulatory requirements but also effectively conveys brand image and product information.