REENYOUNG greeting card printing requires exquisite craftsmanship, complementing the design, paper, and printing. Below, we’ll introduce the process of greeting card printing to give you a basic understanding of how beautiful cards are created.

Greeting card printing incorporates nearly every printing technique, including offset printing, screen printing, hot stamping, embossing, gold sprinkling, and spot UV varnishing, to enhance the visual aesthetic. Greeting cards destined for the European and American markets, in particular, utilize a wide range of printing techniques, adding various decorative touches to enhance the otherwise ordinary cards. The following describes some of the main techniques used in greeting card printing:

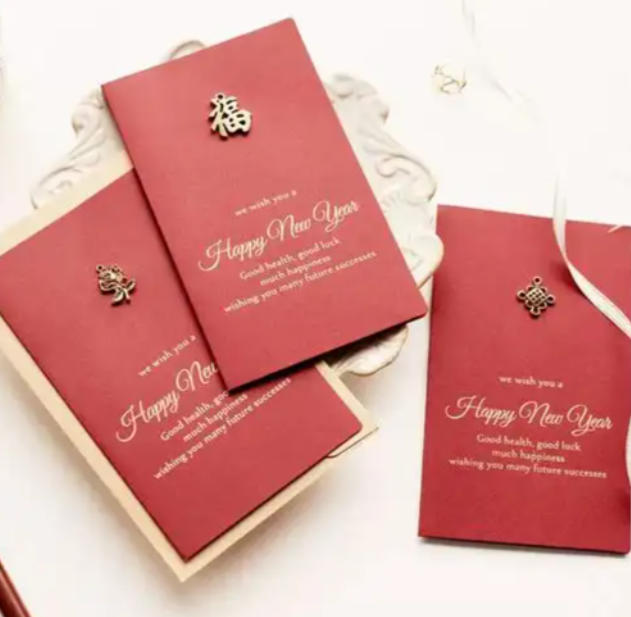

1. For greeting card printing, we recommend using warm and soft images. Printing on 300g white cardstock is recommended. Sparkling simulated crystals can be affixed to the card for a striking visual impact. Customization can be tailored to the overall style of the card and the color of the desired attachment area.

2. Greeting card printing can be done in two layers: a film layer on top and white cardstock on the second. The film is typically UV-printed, with a white ink primer applied in the appropriate locations, and the white ink applied as the final color. This type of product requires high printing precision and requires multiple steps, including hot stamping, front card printing, and back card printing. The transparency of the film allows portions of the back card’s design to show through. Because the film is printed with a layer of transparent ink, it creates a different color when overlaid with the back card’s design. The edge of the second layer is hot-stamped with laser holographic silver foil, creating a laser holographic gold effect when overlaid with the first card. A cartoon image is also embellished on the first layer of film, making this a unique card that will be treasured.

3. Applying a gold sprinkle technique to greeting cards creates a shimmering, striking visual effect. One method involves mixing gold powder with varnish and screen-printing it directly onto the card surface; the other involves screen-printing the varnish first and then applying the gold powder using a gold sprinkler. The first method produces a less radiant gold effect than the second, but it is more durable. The key to this technique is to ensure that the color of the gold powder coordinates with the surrounding color scheme and that the gold powder has strong adhesion to the varnish. Otherwise, the card will be left with an awkward, dusty appearance!

4. Decorating your card with small silk flowers or silk ribbons can add a touch of elegance and refinement. However, be mindful of the silk’s color palette and avoid spilling the glue, as this will significantly diminish the card’s aesthetic appeal.

This concludes our greeting card printing process. If you require large-scale printing, please contact us at https://reenyoung.com/contact. REENYOUNG Paper Card Printing will provide you with the most satisfying printing services!