There are many laptops of various sizes on the market, including practical office laptops, promotional laptops, and gift laptops, with different uses. Many companies hope to print laptops with their own company logo. They can choose which size and cover to choose from, but it is not very clear and they do not know which one is suitable for them. As a necessity for daily learning and office work, laptops may seem ordinary, but the printing process behind them integrates materials science, mechanical engineering, and design aesthetics. This article will take you behind the scenes of notebook printing to understand how a blank sheet of paper can be transformed into a beautiful notebook.

1、 Conventional printing sizes for notebook printing:

16K – Cover size (270 * 210mm) – Core size (258 * 188mm)

24K – Cover size (235 * 175mm) – Core size (210 * 190mm)

32K – Cover size (218 * 154mm) – Core size (208 * 144mm)

48K – Cover size (187 * 122mm) – Core size (170 * 97mm)

56K – Cover size (145 * 105mm) – Core size (128 * 83mm)

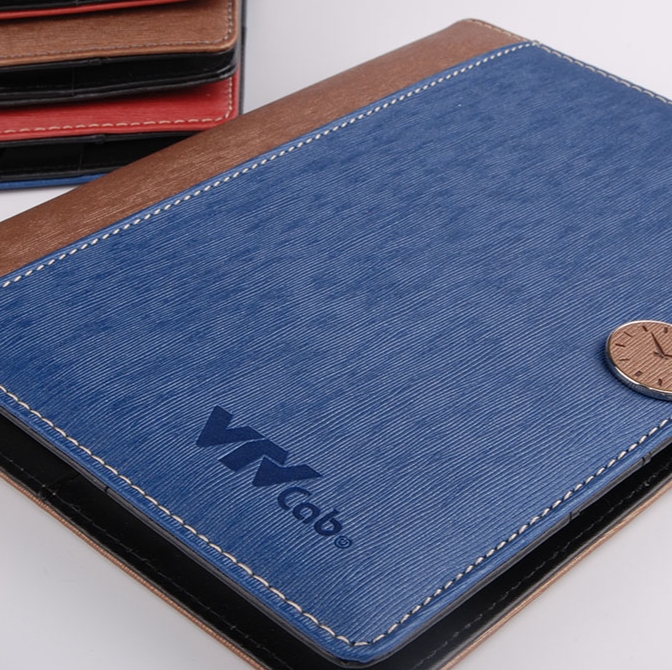

Material: ordinary PU, high-end PU (color changing PU), cowhide. General minimum order quantity: 500 copies, color pages can be printed. The same style can be made in different sizes (16K, 24K, 32K, 48K, 56K). Notebook cover materials commonly used include PU, leather, PP, fabric, and metal.

Binding forms: flat, loose leaf, ring, and hardcover.

Incorporating corporate advertisements (such as company logos, personalized decorations, etc.) into the cover, or inserting pens, documents, cards, and business cards beyond the recorded content, to promote corporate culture and brand image, is not only an elegant and practical traditional cultural gift, but also a messenger to promote corporate image and product advertising. Laptops are widely used in various fields such as conferences, celebrations, gifts, promotions, housewarming, and welfare. They have the characteristics of long-lasting advertising information and strong impact, and are ideal promotional materials for spreading brands and enhancing corporate image.

2、 The core process of notebook printing

1. Final design draft

Layout and bleeding lines: Designers need to reserve a 3-5mm “bleeding line” (edge cutting area) to avoid cutting text or patterns after cutting.

Color mode: Printing uses the CMYK four-color (cyan, magenta, yellow, black) overlay principle, which is different from the RGB mode of electronic screens. Pantone spot colors are used for special color requirements (such as corporate logos).

Paper selection: Common paper types include:

Daolin paper: smooth writing, suitable for use with fountain pens;

Copperplate paper: with a smooth surface, often used for covers;

Recycled paper: environmentally friendly but prone to roughness.

2. Plate making and printing

CTP plate making: Computer to Plate technology replaces traditional film plate making, with higher accuracy and an error of less than 0.1mm.

Printing method:

Offset printing: mainstream technology, through rubber roller transfer printing, suitable for large-scale production;

Digital printing: No plate printing, flexible support for small batch customization;

Screen printing: used for special effects such as local UV and hot stamping.

3. Post processing

Cutting and creasing: The CNC cutting machine cuts large printed materials into single pages, and the creasing machine shapes the cover creases.

Binding process:

Wireless adhesive: Low cost, but prone to delamination due to frequent flipping of pages;

Lock wire glue installation: Double fixation of wire and glue, can be spread 180 ° flat;

Horse riding nail: suitable for booklets with fewer than 64 pages.

Surface treatment: lamination (bright film/matte film), hot stamping, embossing and other processes enhance the texture.