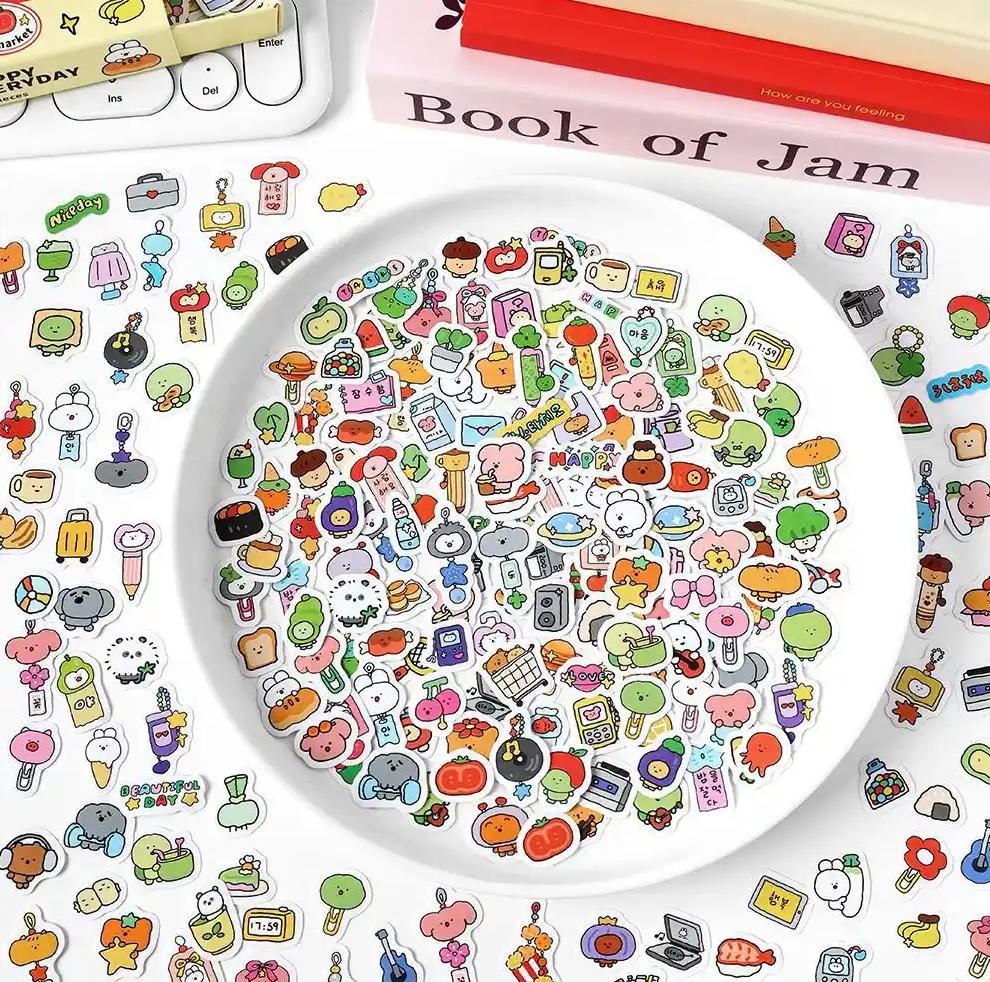

Sticker Printing:Stickers are adhesive-backed paper used for pasting. Various pictures and photos are printed on the back of the paper. These are the common stickers on the market today, which can be pasted onto various products. Their application range is very wide, making them a major product in the printing industry. They come in various patterns, colors, and varieties, and most are for single use only.

Self-Adhesive Printing:Self-adhesive printing typically uses screen printing. In recent years, due to the development of offset printing technology, offset printing has also been adopted. Film preparation and plate making are required before printing. Post-printing processing involves necessary cutting. When the design has special requirements, some special processing techniques will be added, but generally the complexity is not high. For some roll-to-roll self-adhesive printing presses, printing, lamination, hot stamping, die-cutting, etc., can be completed in one step.

Self-Adhesive Sticker Production Process: Unwinding

1. Intermittent: There is no tension change during roll unwinding, so no adjustment is required. 1. **Slow Unwinding:** Used on flatbed and rotary label presses. Because these machines lack paper positioning and correction devices, the roll paper ends must be clean to ensure accurate registration during printing.

2. Continuous Type:Used on rotary label presses. Since paper tension changes with the roll paper diameter and speed, this device has automatic or manual tension control mechanisms and roll paper correction devices to ensure smooth paper feeding and print quality.

Hot Stamping:

Flatbed: Used on flatbed and rotary label presses; low speed.

Roller-on-Roller: Used on rotary label printing machines; high speed; continuous hot stamping is possible, but rarely used; gold printing is commonly used instead.

Printing:

Flatbed: Suitable for small areas and simple designs, such as price tags and barcodes.

Roller-on-Roller: Suitable for labels with solid areas and general designs; simple color halftone printing is possible.

Rotary die-on printing is suitable for printing various graphic labels, especially high-end color halftone labels.

UV Printing: Adding UV drying to the above three printing methods allows for printing on thin-film self-adhesive materials.

Hot Stamping First, Then Printing

On equipment without UV drying, ordinary inks are used. The disadvantage is that the design of the printed pattern is limited.

Printing First, Then Hot Stamping

Applied to equipment with UV drying devices, the ink dries quickly, and hot stamping is applied on top. The hot stamping pattern can be designed arbitrarily, without being limited by the ink. Suitable for high-end label printing, it is an advanced production process. Jiarunlong Printing uses advanced foreign equipment for more precise and efficient printing.

Varnishing

Solid Varnishing: Applying a layer of varnish to the ink surface aims to protect the ink layer, prevent moisture and water damage, and improve surface gloss. It can replace lamination and uses UV drying.

Lamination

Laminating paper or film materials aims to protect the ink, prevent water and moisture damage, increase label strength, and enhance the three-dimensional effect of the graphic. Lamination is divided into lamination with a backing paper and lamination without a backing paper. The latter is more commonly used due to its lower cost. Depending on the process requirements, there are also composite transparent films and matte films, with the former being more widely used.

Perforation

This is not widely used, mainly for computer-printed labels. The requirement is to punch positioning and driving holes on both sides of the label, or for labels used on price tag printers, a hole is required in the center for positioning and driving.

Die-cutting

Die-cutting of self-adhesive labels is a semi-through process, meaning only the surface material is cut through while the backing paper remains. There are two processing methods: flat die-cutting, suitable for various label printing machines, manual plate making, low cost, short plate-making cycle, but low viscosity, suitable for short-run printing jobs. Currently, almost all domestic label factories use flat die-cutting. The other is rotary die-cutting, used on rotary label-to-rotary equipment, fast speed, high die-cutting viscosity, suitable for long-run jobs, but the disadvantages are high plate-making costs and long cycle time. Currently, domestic manufacturers generally process their die-cutting rollers overseas.

Paper Collection

This can be broadly divided into sheet-cutting collection and folding collection.

Notes on Sticker Printing:

1. Adhesive for Self-Adhesive Stickers: When printing self-adhesive stickers, attention must be paid to the choice of adhesive to ensure a good adhesion. This is a crucial factor affecting the quality of the self-adhesive stickers. Jiarunlong Printing uses imported adhesives from a certain country, effectively reducing or even eliminating problems caused by adhesives.

2. The Neatness of Self-Adhesive Stickers: During self-adhesive sticker printing, it is essential to maintain the neatness of the product, especially ensuring that the edges are clean and complete. Otherwise, the quality of the printed self-adhesive stickers will be affected.